Select Language

Select Language

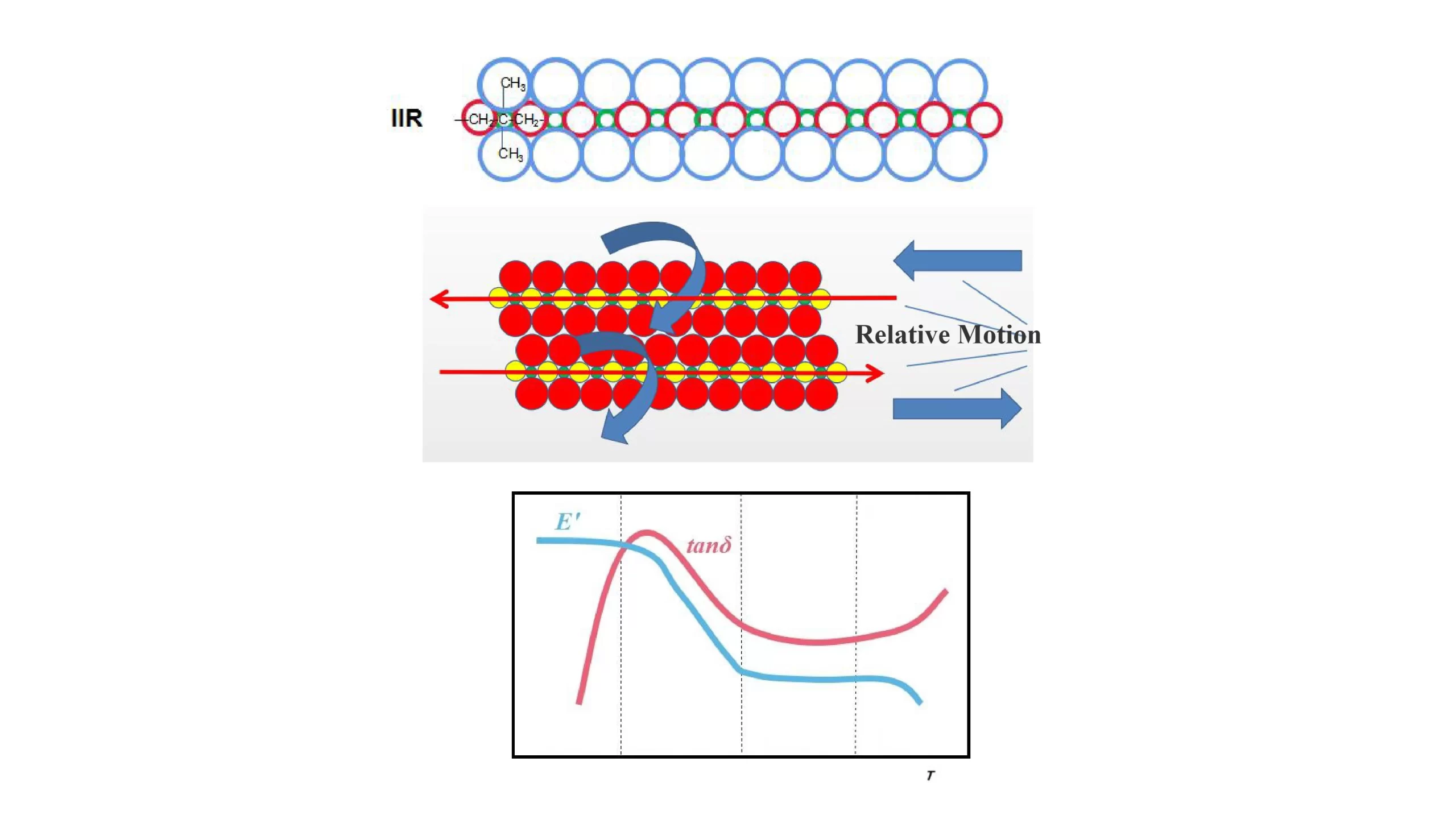

Damping Vibration-Absorbing Elastomer Materials

Preparation technology

function and characteristic

Representative products

application area

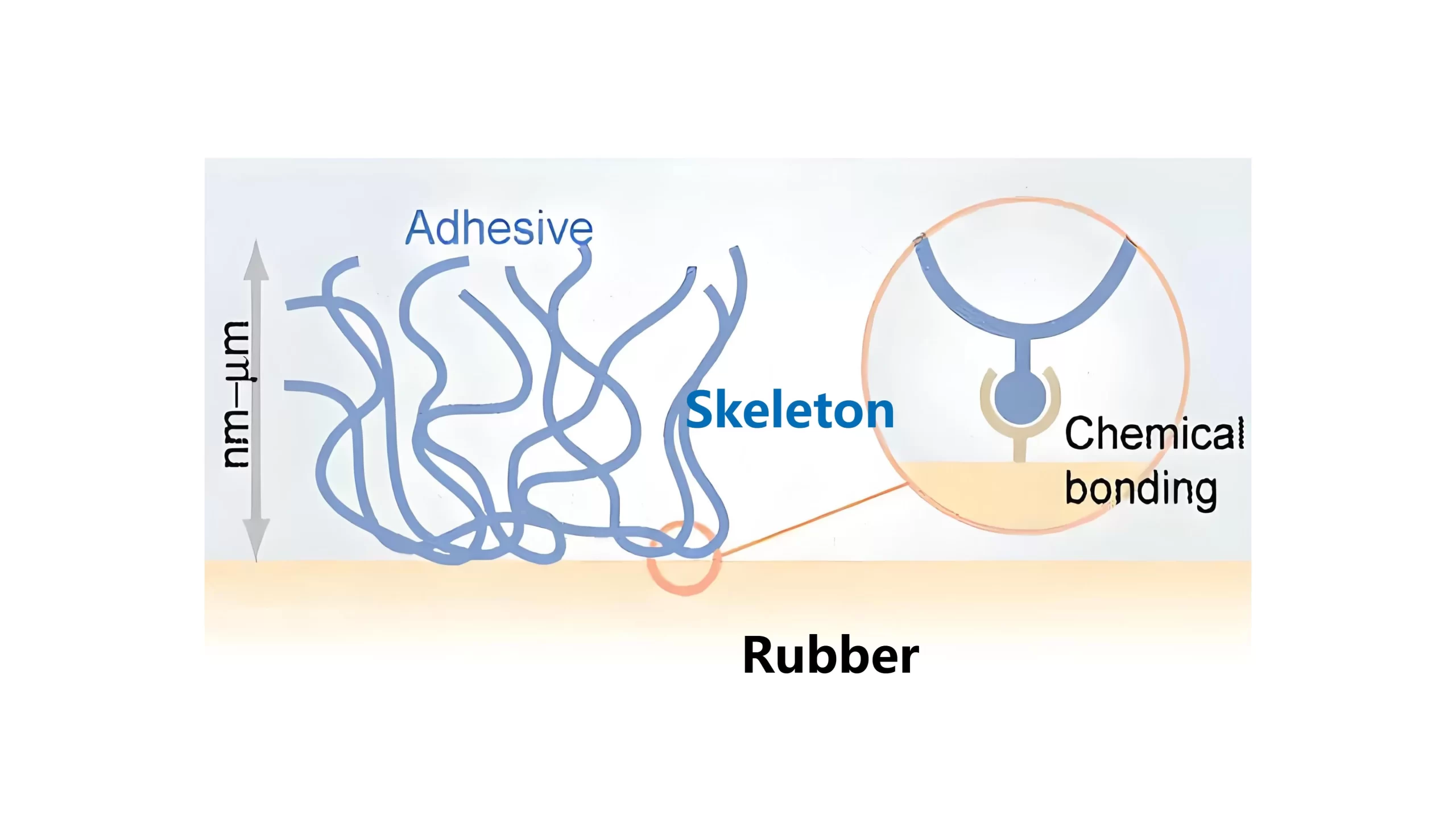

Composited Skeleton And Elastomer Materials

Preparation technology

function and characteristic

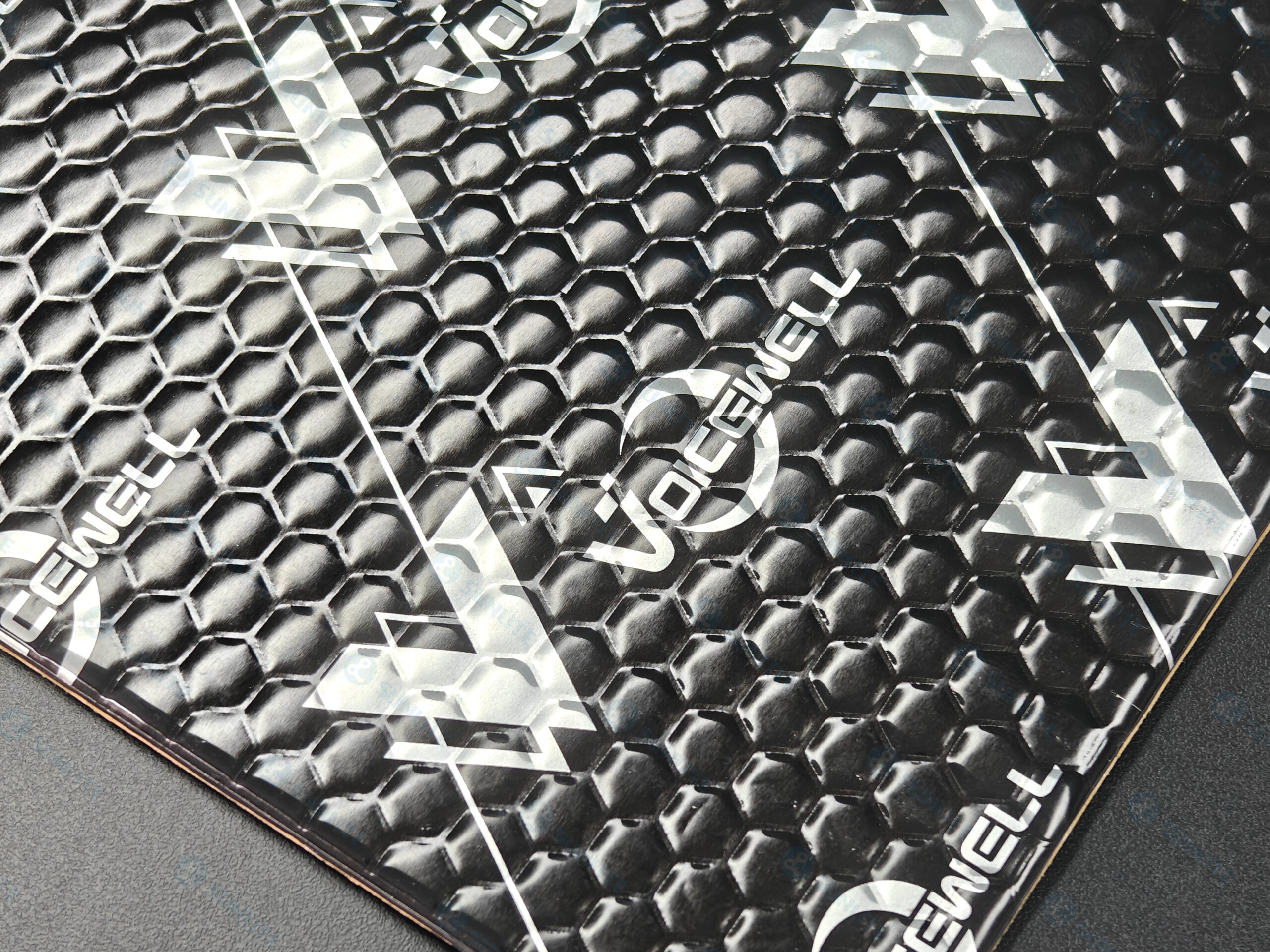

Representative products

application area

Halogen-Free Flame-Retarded Elastomer Materials

Preparation technology

function and characteristic

Representative products

application area

High Impact Elastomer Materials

Preparation technology

function and characteristic

Representative products

application area

Thermally Conductive Flame Retardant Phase-Change Elastomer Materials

Preparation Technology

The multifunctional integration of materials is achieved by combining flame retardants, phase-change materials, and a rubber-based matrix.

During preparation, appropriate flame retardants (e.g., phosphorus-nitrogen compounds) and phase-change agents (e.g., polyethylene glycol) are selected.

Microencapsulation technology is adopted to encapsulate these components, followed by uniform dispersion within the rubber matrix through mixing processes1.

Finally, compression molding is applied to fabricate the composite, ensuring balanced flame retardancy, phase-change energy storage capability, and mechanical/thermal stability.

Function And Characteristic

Representative products

application area

Insulating And Protective Elastomeric Materials

Preparation Technology

Function And Characteristic

Representative products

application area

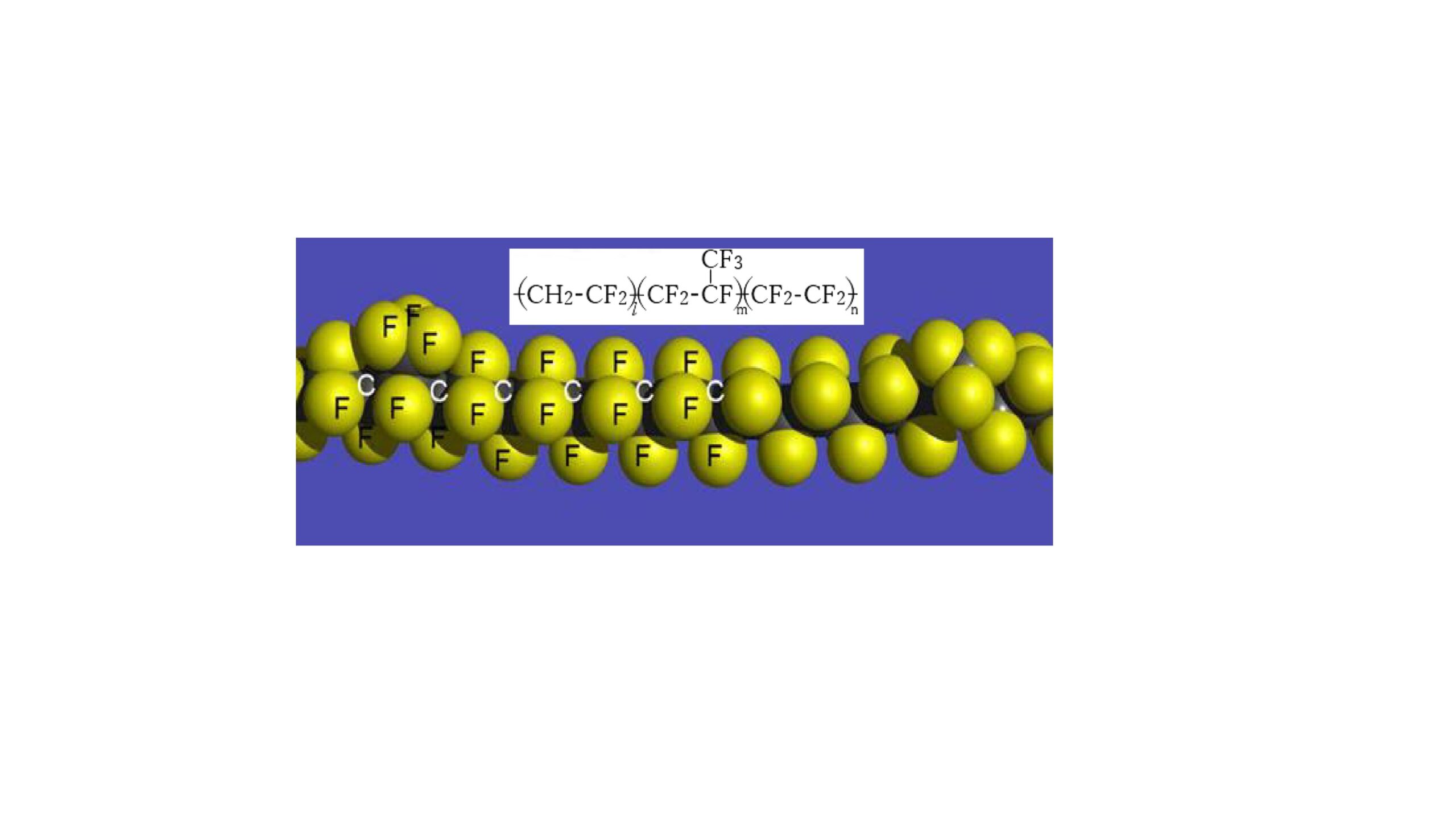

Elastomer Materials Resistant To Special Media

Preparation Technology

Function And Characteristic

Representative products

application area

Antistatic Elastomer Materials

Preparation Technology

Function And Characteristic

Representative products

application area

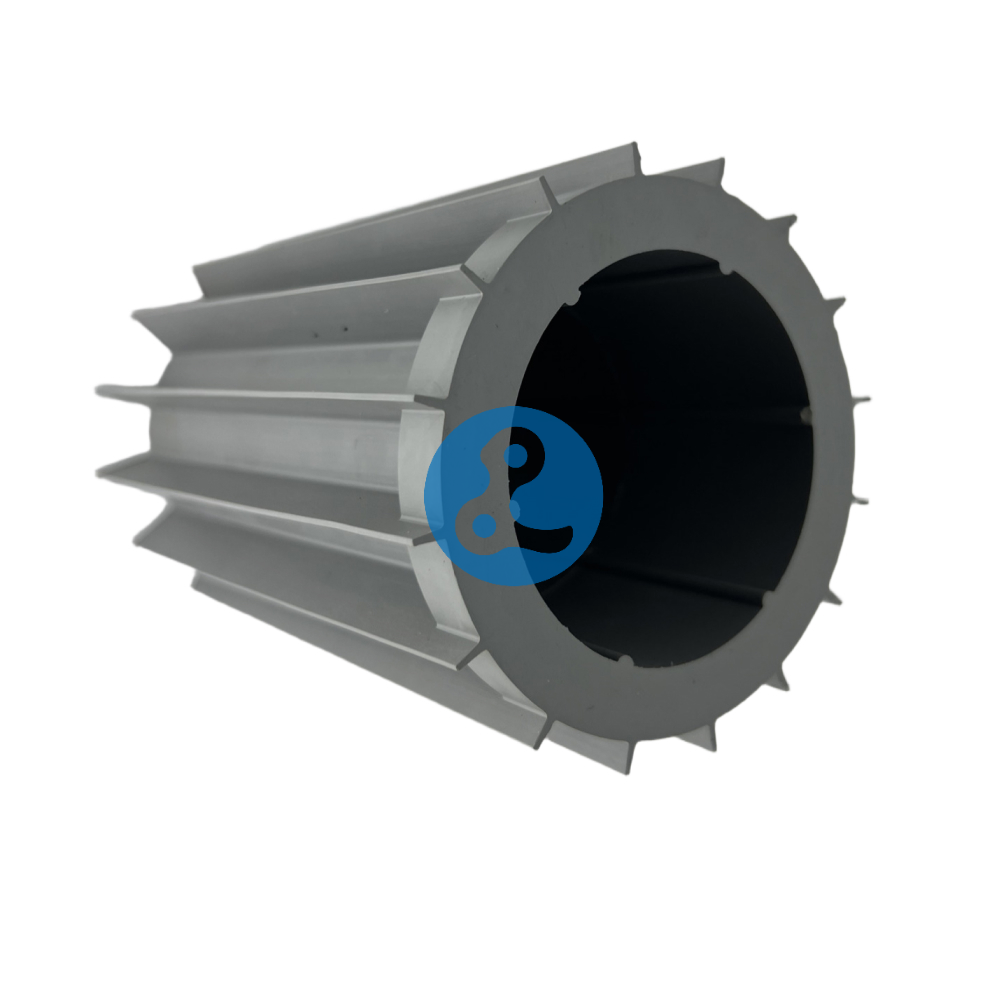

Carbon Fiber/Glass Fiber Reinforced Polymer

Preparation Technology

Function And Characteristic

Representative products

application area